Sports ground

Plastic track, also known as all-weather track and field sports track, it consists of polyurethane prepolymer, mixed polyether, EPDM rubber particles or PU particles, pigments, additives, fillers.

The plastic track has the characteristics of good flatness, high compressive strength, appropriate hardness and elasticity, and stable physical properties, which is conducive to the speed and technology of athletes, effectively improving sports performance and reducing the rate of falls. Plastic runway is composed of polyurethane rubber and other materials, with a certain degree of elasticity and color, with a certain degree of anti-ultraviolet ability and aging resistance is internationally recognized outdoor sports ground floor materials.

Scope of application

It is used for kindergartens at all levels and types of schools and professional stadiums, track and field runways, national fitness paths, indoor gymnasium training runways, playground road paving, indoor and outdoor runways, stadiums, parks, residential areas and other activity venues.

Main classification

Generally speaking, the usual runway refers to the track and field runways of plastic runways in schools and professional stadiums at all levels and types. There are standard runways and non-standard runways: standard runways refer to 400 meters in circumference and 36.5 meters in radius (there are also 36 meters and 37.898 meters in radius); Non-standard runway refers to adjusting the radius and perimeter of the playground appropriately according to the shape and size of the playground land area, common have a circumference of 200 meters, 300 meters and so on.

Plastic runway structure type

Wood Flooring System

Sports wood floor is an important part of the construction of sports venues, is the carrier of competition and training, its comprehensive performance directly determines the level of the event and the results of training.

Floor structure practices

In order to meet the venue requirements of high-standard basketball special events, it is recommended that the wood floor adopt "double-layer" wood keel wood floor system, and the panel adopts imported North American maple wood floor.

- 20mm thick surface floor

- 12mm thick wool floor

- 1mm damping and sound insulation film

- Upper 25*60 * 2400LVL composite keel

- "Butterfly" elastic pad

- Lower 25*60 * 2400LVL composite keel

- Wedge leveling pad, 0~25mm

- One layer of plastic moisture-proof membrane

After the 2008 Beijing Olympic Games, domestic large-scale events have put forward higher requirements for sports wood flooring. Among them, the performance of sports wood flooring needs to be tested and then the next plan is determined. The new venues will consider the sports wood flooring and venue positioning, event level and post-match operation to determine the products.

Sports wood flooring has already passed the strict testing of the National Sporting Goods Quality Supervision and Inspection Center, all of which have reached the "DIN18032" standards stipulated by the FIBA and are widely used in many large domestic venues. At the same time, our agent of the United States "AACER" domestic translation of "A Shang" sports wood flooring is also the mainstream products in the same industry.

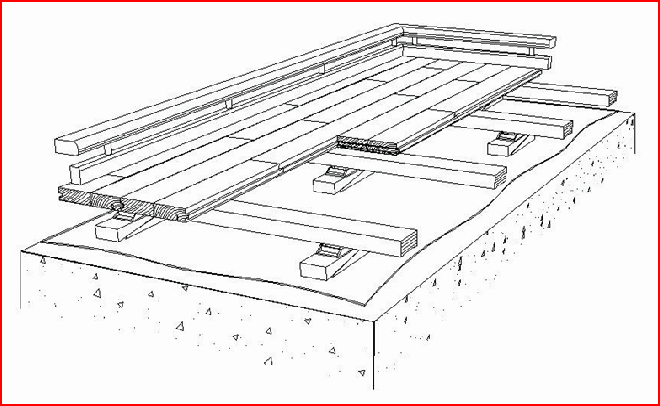

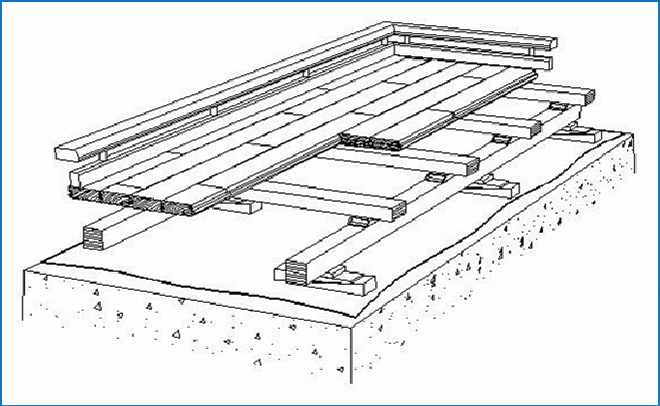

Installation Diagram of Wood Floor System

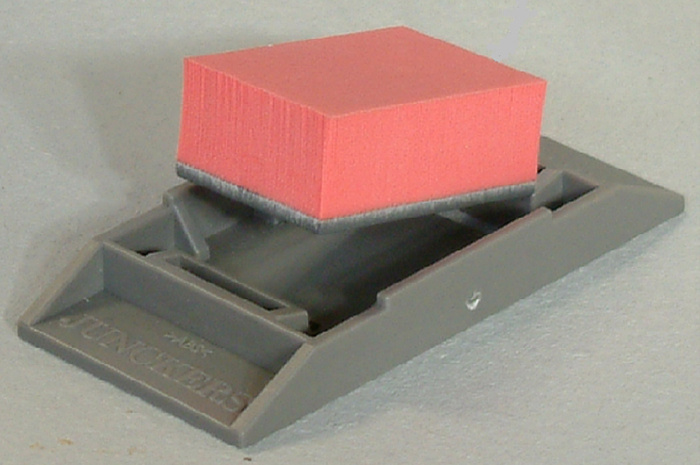

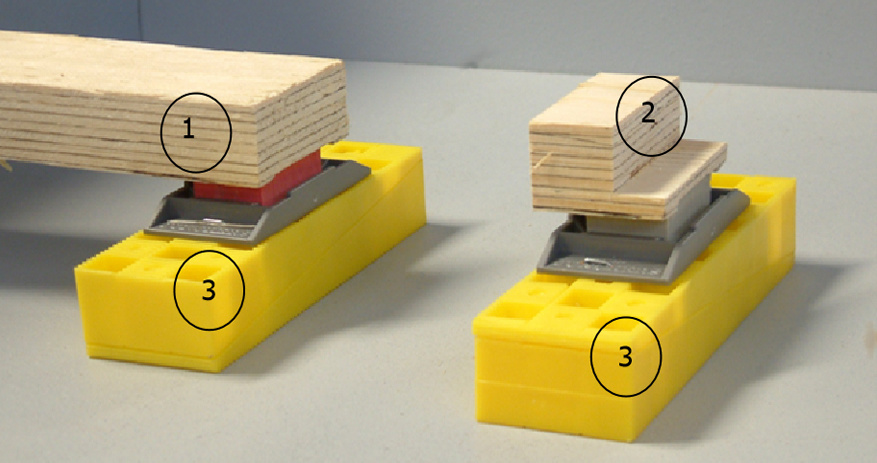

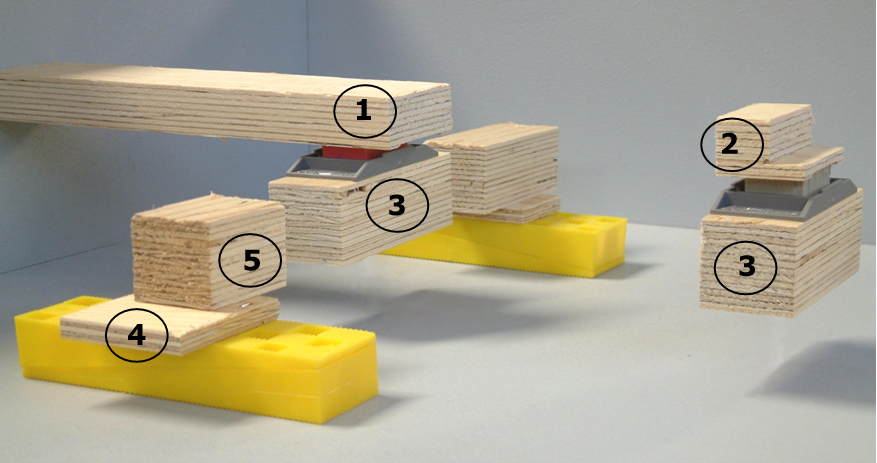

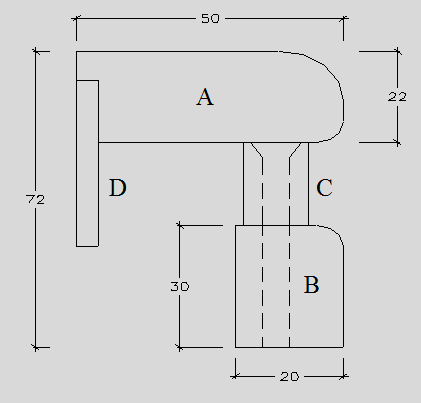

The flexible LVL keel (Figure A), which is completely manufactured according to the "construction grade" standard, is the key to meet the DIN standard for kinetic energy absorption. Completely different from ordinary solid wood keel, LVL keel has eliminated all the internal stress of the wood itself in the cutting process and combined together in the same direction again, showing elasticity under high strength is possible.

J-LOCK elastic pad technology (Figure B) uses high-density polystyrene instead of rubber, which reduces environmental pollution and increases service life. At the same time, the effective limit control ensures that the deformation of the wooden floor is within the controllable range.

Because the domestic construction standards are different from foreign countries, the self leveling construction technology is rarely used except for special requirements. For the wood floor system, the flatness of the foundation is innate and fatal. For imported systems, because it is based on self-leveling or higher decorative standards to carry out the design, so for the domestic requirements are not very strict concrete base, hard installation can not reflect the value.

Our adjustable leveling system (fig. 3) is a wedge-shaped cushion block made of high-strength ABS material. when the two cushion blocks are bitten together, the adjusted height is 1mm for each bite ruler adjusted, and the adjustable height of all systems is 25mm. Can fully meet the domestic building decoration ground error value.

Based on the double keel system, our leveling pad is placed at the bottom end of the lower keel. The elastic pad is located in the middle of the two adjustable flat fulcrums of the lower keel, and the upper keel is perpendicular to the lower keel and fixed with the elastic pad to form a new elastic structure.

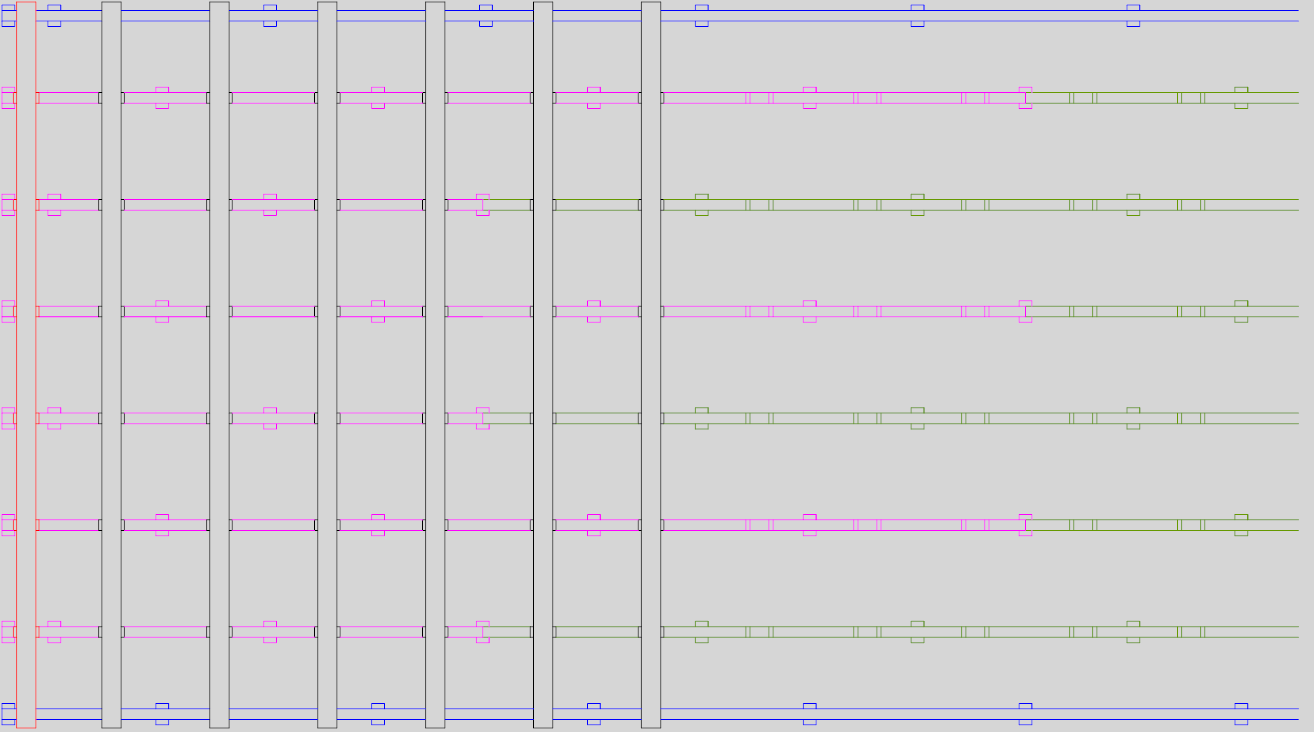

The keel arrangement principle of the double dragon bone system is 400mm in the middle distance and 400mm in the elastic pad arrangement principle. It should be noted that in the process of keel erection, attention should be paid to the wrong head arrangement to prevent uneven stress caused by the street appearing on the same line.

When using fixed-length pavement, whether single keel structure or double keel structure, we must carry out accurate measurement. As shown in the figure to the right, all surface floor joints must be placed in the middle of the upper keel under the assumption of a fainted floor. Moreover, the installation of the surface floor should also be staggered, and the adjacent slat joints cannot be in line to ensure uniform stress on the floor system.

Assembled skirting board system, fully considering the evacuation of moisture, set up the surface cover plate 50mm away from the wall, and support it with stainless steel column and vertical plate in the middle to form an effective spatial structure. When all around the exhaust skirting board, the air will flow naturally, and the moisture in the lower structure of the floor system will be evacuated in time.

Keywords: plastic runway, wood floor runway