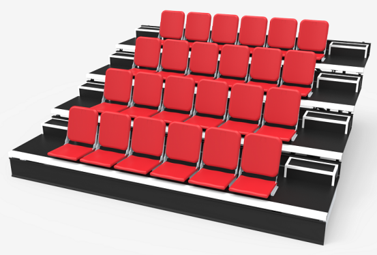

Grandstand Seats

- The seat is mainly made of high-quality reinforced polypropylene material and adopts rotational molding process. The rotomoulded seats required to be provided must comply with national standards and industry standards.

- The design, shape and installation method of the seat should meet the international general requirements, not only beautiful appearance, but also comfortable seat feeling, while taking into account the convenience of installation, maintenance and management.

- The seat bracket is required to be formed by aluminum alloy die casting. The seat is overturned with double torsion springs, and the structure is all hidden inside the bracket. It is required that fingers will not be pinched during the overturning of the seat cushion. About chair surface length 41 * width 42 * chair back height 42 * chair back width 43cm weight: 6.4kg

Fixed seat

Seat performance:

1. Good mechanical properties, high strength and impact resistance.

2. Environmental safety, weather resistance, anti-aging, high and low temperature resistance.

3. Uniform color.

Seat and Bracket Attachment:

Steel pipe/steel plate stamping parts are generally used.

Support installation method:

Sub-front type, (directly installed on the steps) floor type, mobile type, suspended type, vertical type.

Bracket surface treatment:

Electrostatic spray.

(color: red, yellow, blue, green, orange)

Structure Diagram

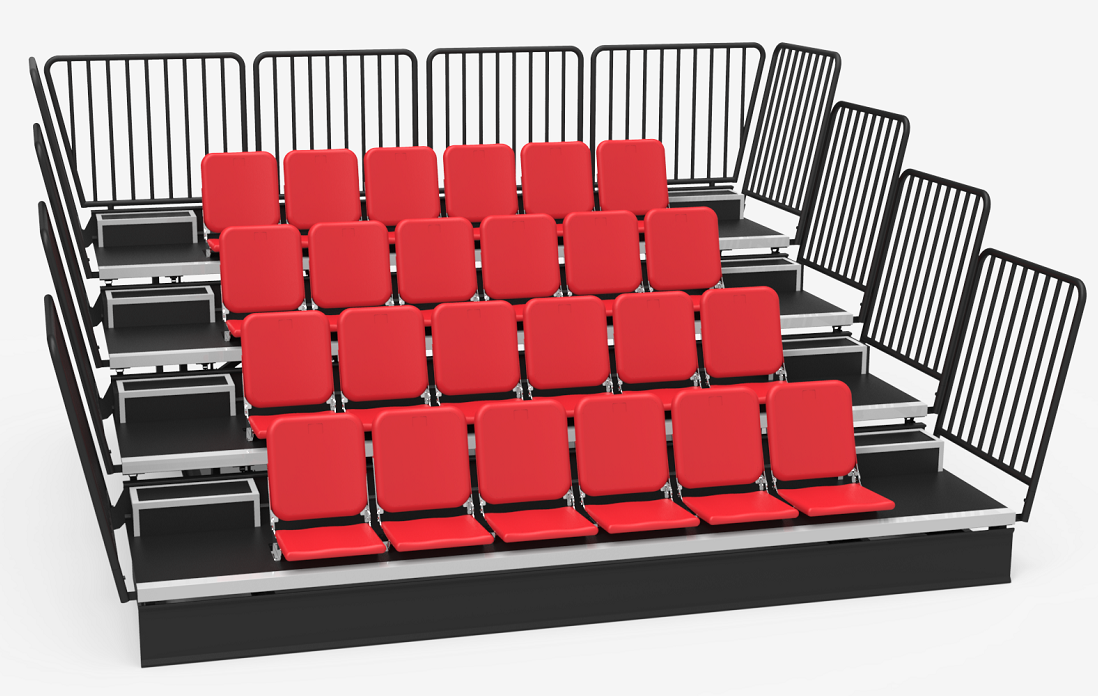

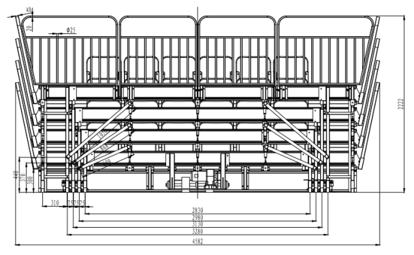

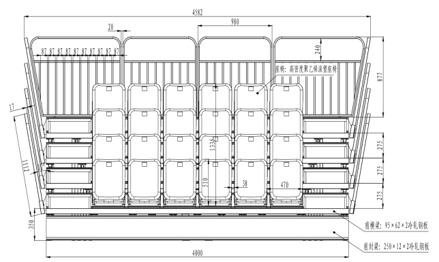

Overall design of activity stands

According to the stadium floor plan, the actual situation of the scene to deepen the design, combination selection, color modeling can be freely selected, in line with national standards.

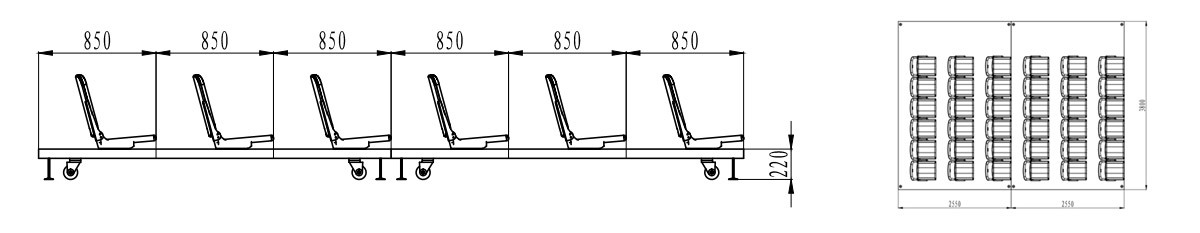

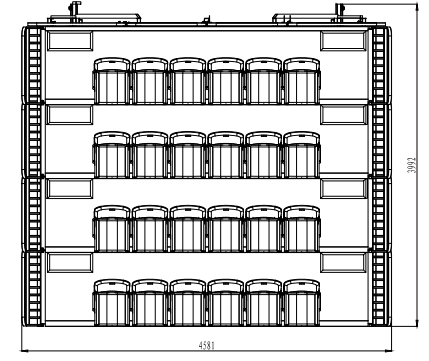

The height of the first floor of the activity stand is 350MM, the height of the podium side is 265MM, the height of the other three sides is 290MM, and the row spacing is 850MM. The overall expansion and contraction of the stand is not obvious deviation, non-directional deviation is ≤ 50mm, and the overall noise dB≤ 40dB.

Folding seat

★The seat equipped with the product shall be made of high density polyethylene as the main raw material and made by rotational molding process. After the seat is assembled, the width is 410MM, the height is 420MM, the depth is 420MM, and the height after the seat is folded is 200MM. Static load of seat (150kg,5 min), static load of seat back (120kg,1min) when the seat back is turned down.

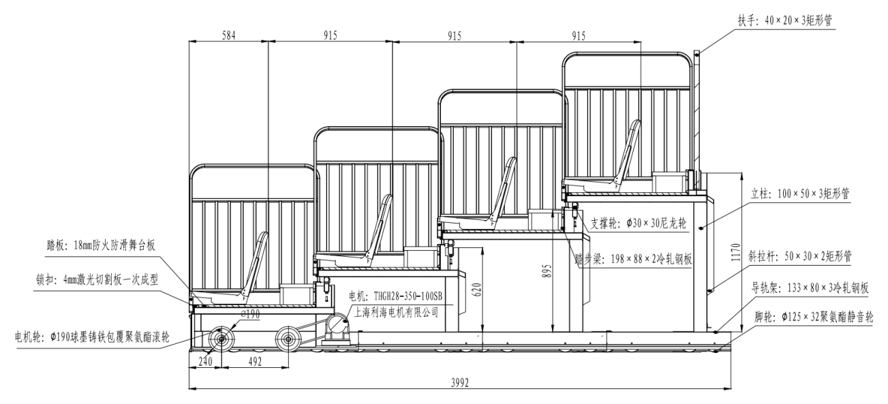

upright support system

The main support adopts a vertical structure, the column adopts a 50*100*3mm high-quality rectangular tube, and the cable-stayed rectangular tube (the cable-stayed rectangular tube adopts a 50*30*2mm high-quality rectangular tube) and the front plate back plate cooperate to form a stable frame structure.

The upper guide rail is formed by bending 2mm cold rolled galvanized steel sheet at one time. The coated upper guide rail is built with a high-strength nylon guide wheel with an outer diameter of 33mm. The adjustable top wheel is designed on the upper guide rail. The top wheel is made of high-strength nylon material with an outer diameter of 31mm. The bottom of the top wheel is equipped with adjustable screws, and the adjustable height is not less than 10mm.

The lower interconnected guide rail adopts double-bearing polyurethane casters, and the load of a single caster is above 360KG. The casters meet the relevant requirements of GB/T14688-93 industrial casters. The overlapping position of adjacent guide rails shall not be less than 250mm, and the guide rails shall be integrally bent and formed by high-quality 3mm hot-rolled steel plates.

Seat Drive System

The products to be cast shall be driven by independent four-wheel drive, with cast iron wheel having an outer diameter of 190mm and a wheel width of 100mm. The inside shall be made of high-quality ductile iron, and the outside shall be covered with wear-resistant polyurethane with a thickness of 10mm. The hardness shall reach Shore 90-93A.

It adopts light gear reduction motor, power 0.75W, transmission ratio 1:100, 24V safety voltage control system.

Pedal and its connecting piece

Class I 18mm plywood is used for the pedal. The installation of the pedal adopts mosaic design. The surface of the pedal must be paved with high wear-resistant, fire-resistant and non-slip PVC surface. I-shaped connectors of aluminum alloy are used between the pedals.

The front and rear bearing beams are made of 2mm cold-rolled galvanized steel plate, which is integrally roll-formed after being punched by a numerical control punch, without welding.

Safety guardrail and auxiliary parts

The safety guardrail material is 40*20*2 high-quality rectangular pipe and φ25*2 high-quality steel pipe welded together. The vertical pipe structure is not easy to climb. The effective height of the guardrail is ≥ 1100mm (the effective height of the front guardrail can be adjusted to 800mm due to the requirements of the line of sight), and the gap between the guardrails is ≤ 100mm. The design of guardrail shall give full consideration to the overall safety, and shall meet the requirements of horizontal static load of 60 KG/M and vertical static load of 100 KG/M. The guardrail shall be disassembled and installed freely, and shall not affect the expansion and contraction of the product. A special aluminum alloy anti-skid strip is arranged on the front bearing beam of each row of bed frames, with glossy PVC anti-skid strips inlaid inside, and an auxiliary step with half the height of half of the height of each row. Side curtains are installed on both sides of the activity stand, and the side curtains are made of gray PVC mesh fabric.

Keywords: grandstand seat, fixed seat

Engineering renderings